khoom

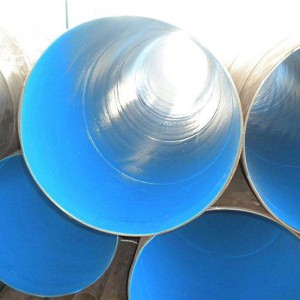

Roj kuj coatings epoxy anti-corrosion static conductive xim

NTAUB NTAWV

- Khoom nta

- Khoom siv

- Cov ntaub ntawv technical

- Txoj kev tsim kho

- Kev kho saum npoo

- Thauj thiab Cia

- Pob

* Khoom nta:

1. Cov xim zaj duab xis yog tawv, muaj kev cuam tshuam zoo thiab adhesion, yoog raws, cuam tshuam tsis kam thiab abrasion tsis kam;

2. Zoo roj kuj, corrosion kuj thiab zoo electrostatic conductivity.

3. Nws yog resistant rau corrosion, roj, dej, acid, alkali, ntsev thiab lwm yam tshuaj.Lub sij hawm ntev tsis kam rau cov roj av thiab cov dej tank ntawm 60-80 ℃;

4. Cov xim zaj duab xis muaj zoo heev los tiv thaiv permeability rau dej, roj crude, refined roj thiab lwm yam corrosive media;

5. Kev ua kom qhuav zoo heev.

* Cov khoom siv:

Nws yog tsim rau aviation kerosene, roj av, diesel thiab lwm yam khoom roj tso tsheb hlau luam thiab nkoj roj tso tsheb hlau luam thiab cov roj tso tsheb hlau luam hauv cov roj av, roj refineries, tshav dav hlau, roj tuam txhab, chaw nres nkoj tuam txhab thiab lwm yam lag luam.

Anti-corrosion txheej rau tank tsheb thiab roj kav dej.Nws kuj tseem siv tau rau hauv lwm qhov kev lag luam uas yuav tsum muaj kev tiv thaiv zoo li qub.

*Technical Datas:

| Yam khoom | Txuj |

| Xeev hauv lub thawv | Tom qab sib tov, tsis muaj lumps, thiab lub xeev yog uniform |

| Cov xim thiab cov tsos ntawm cov xim zaj duab xis | Txhua yam xim, xim zaj duab xis tiaj tus thiab du |

| Viscosity (Stormer Viscometer), KU | 85-120 : kuv |

| Lub sij hawm qhuav, 25 ℃ | nto ziab 2h, nyuaj ziab ≤24h, kho tag nrho 7 hnub |

| Flash point, ℃ | 60 |

| Thickness ntawm Dry film, um | ≤1 |

| Adhesion (hloov txoj kev hlais), qib | 4-60 |

| Kev cuam tshuam lub zog, kg / cm | ≥50 |

| Flexibility, mm | 1.0 |

| Alkal tsis kam, (20% NaOH) | 240h tsis muaj blistering, tsis poob tawm, tsis muaj xeb |

| Acid tsis kam, (20% H2SO4) | 240h tsis muaj blistering, tsis poob tawm, tsis muaj xeb |

| Dej ntsev resistant, (3% NaCl) | 240h tsis muaj foaming, ntog, thiab xeb |

| Thaum tshav kub kub tsis kam, (120 ℃) 72h | zaj duab xis yog zoo |

| Kev tiv thaiv roj thiab dej, (52 ℃) 90d | zaj duab xis yog zoo |

| Deg resistivity ntawm xim zaj duab xis, Ω | 108-1012 ib |

Tus Qauv Ua Haujlwm: HG T 4340-2012

* Kev tsim kho:

Txau: airless spraying lossis cua txau.Kev kub siab airless txau yog pom zoo.

Txhuam / dov: Pom zoo rau thaj chaw me me, tab sis yuav tsum ua tiav cov txheej txheem qhuav zaj duab xis tuab.

* Kev kho deg:

Tshem tawm cov plua plav, roj thiab lwm yam impurities nyob rau saum npoo ntawm cov khoom coated kom huv si, qhuav thiab tsis muaj kuab paug.Qhov saum npoo ntawm cov hlau yog sandblasted los yog mechanically derusted.

Qib, Sa2.5 lossis qib St3 raug pom zoo.

* Thauj thiab Cia:

1. Cov khoom no yuav tsum tau muab kaw thiab khaws cia rau hauv qhov chaw txias, qhuav, qhov cua, kom deb ntawm hluav taws, tsis muaj dej, tsis muaj dej pov thawj, qhov kub thiab txias, thiab raug tshav ntuj.

2. Yog tias cov xwm txheej saum toj no tau ua tiav, lub sijhawm khaws cia yog 12 lub hlis txij li hnub tsim khoom, thiab nws tuaj yeem siv tom qab dhau qhov kev xeem yam tsis muaj kev cuam tshuam rau nws cov nyhuv;

3. Tsis txhob sib tsoo, hnub thiab nag thaum lub sijhawm khaws cia thiab kev thauj mus los.