khoom

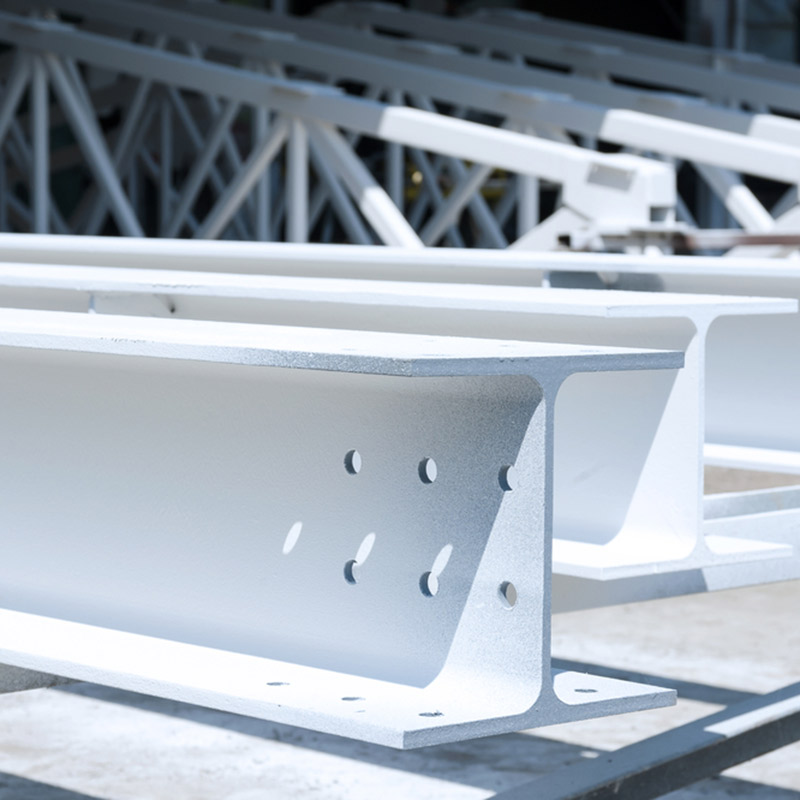

High adhesion los tiv thaiv xeb thiab tiv thaiv corrosion epoxy zinc nplua nuj primer

NTAUB NTAWV

- Khoom nta

- Khoom siv

- Cov ntaub ntawv technical

- Kev kho saum npoo

- Xim Xim

- Txoj kev tsim kho

- Thauj thiab Cia

- Pob

* Khoom nta:

1. Cov xim yog nplua nuj nyob rau hauv zinc hmoov, thiab electrochemical tiv thaiv ntawm zinc hmoov ua rau cov xim zaj duab xis muaj zoo heev anti-xeb kev ua tau zoo;

2. Zoo mechanical zog thiab muaj zog adhesion;

3. Muaj kev hnav zoo heev;

4. Zoo roj tsis kam, dej tsis kam thiab hnyav tsis kam;

5. Nws muaj kev tiv thaiv tsis zoo thiab ua kom sov zoo heev.Thaum lub vuam hluav taws xob raug txiav, cov zinc pos huab tsim me me, qhov kub hnyiab tau tsawg dua, thiab kev ua haujlwm vuam tsis cuam tshuam.

* Cov khoom siv:

Haum rau metallurgy, ntim, nkoj, txuas hniav, yees, roj pipelines, tsheb tsim, steel tua pretreatment kab, steel qauv khoom nto raws li lub hauv paus anti-xeb primer, kuj yuav siv tau rau anti-corrosion txheej ntawm galvanized nto.

*Technical Datas:

| Yam khoom | Txuj |

| Xim thiab tsos ntawm cov xim zaj duab xis | Tom qab nplawm thiab sib tov, tsis muaj zog thaiv |

| Xim zaj duab xis xim thiab tsos | Grey, xim zaj duab xis yog du thiab du |

| Cov ntsiab lus tseem ceeb,% | ≥70 |

| Lub sij hawm qhuav, 25 ℃ | Nto qhuav ≤ 2h |

| Lub zog qhuav ≤ 8h | |

| Kev kho tag nrho, 7 hnub | |

| Cov ntsiab lus tsis-volatile,% | ≥70 |

| Cov ntsiab lus ruaj khov,% | ≥60 |

| Kev cuam tshuam lub zog, kg / cm | ≥50 |

| Qhuav zaj duab xis Thickness, um | 60-80 |

| Adhesion (zoning method), qib | ≤1 |

| Kev zoo, μm | 45-60 : kuv |

| Flexibility, mm | ≤1.0 |

| Viscosity (Stomer viscometer), ku) | ≥60 |

| Dej tsis kam, 48 h | Tsis muaj foaming, tsis xeb, tsis muaj cracking, tsis tev. |

| Ntsev tshuaj tiv thaiv, 200h | tsis muaj blister, tsis muaj xeb, tsis muaj tawg, flake nyob rau hauv lub unmarked cheeb tsam |

Txheem ntawm Tuam Tshoj: HGT3668-2009

* Kev kho deg:

Txhua qhov chaw yuav tsum tau coated yuav tsum huv si, qhuav thiab tsis muaj kab mob.Ua ntej pleev xim, txhua qhov chaw yuav tsum ua raws li ISO8504: 2000 tus qauv ntsuas thiab ua tiav.

- Lub scaled steel yog blasted rau Sa2.5 qib, nto roughness yog 30-75μm, los yog pickled, neutralized thiab passivated;

- Oxide-free steel blasted rau Sa2.5 qib, los yog polished rau qib St3 nrog pneumatic los yog hluav taws xob elastic sib tsoo log;

- Steels coated nrog rhiav primer xim zaj duab xis puas, xeb thiab dawb xeb ntawm zinc hmoov primer yuav tsum derusted ob zaug, dawb xeb raug tshem tawm thiab polished rau St3.

Lwm qhov chaw Cov khoom no yog siv rau lwm cov substrates, thov sab laj nrog peb cov kws tshaj lij.

* Xim Xim:

Cov xim nruab nrab lossis cov coats xws li epoxy, chlorinated roj hmab, high-chlorinated polyethylene, chlorosulfonated polyethylene, acrylic, polyurethane, thiab interpenetrating network.

* Kev tsim kho:

Txau: Tsis yog huab cua txau lossis cua txau.Kev kub siab tsis yog roj txau.

Txhuam / yob: pom zoo rau thaj chaw me me, tab sis yuav tsum tau teev tseg

* Thauj thiab Cia:

1, cov khoom no yuav tsum tau muab kaw thiab khaws cia rau hauv qhov chaw txias, qhuav, qhov cua, kom deb ntawm hluav taws, tsis muaj dej, tsis muaj pov thawj, kub, tshav kub.

2, Raws li cov xwm txheej saum toj no, lub sijhawm khaws cia yog 12 lub hlis txij li hnub tsim khoom, thiab tuaj yeem siv txuas ntxiv tom qab dhau qhov kev xeem, tsis muaj kev cuam tshuam rau nws cov txiaj ntsig.